22 January 2026

Why Annual Maintenance Contracts Are Critical for High-Pressure Industrial Pumps

Industrial Pumps are the backbone of critical industries, operating continuously under extreme pressure, temperature, and load conditions. In such environments, even a brief interruption can result in significant financial losses, safety risks, and prolonged operational downtime.

Despite this, many facilities continue to rely on reactive, breakdown-based maintenance, addressing issues only after failures occur. In high-pressure and mission-critical applications, this approach exposes operations to unnecessary risk and unpredictability.

Annual Maintenance Contracts (AMC) are no longer optional; they are essential for operational continuity and system reliability.

The Real Cost of Unplanned Downtime

Unplanned downtime is one of the most expensive risks in industrial operations. When a critical pump fails unexpectedly, the impact goes far beyond repair costs:

-

Production losses and delayed deliveries

-

Product quality issues and material wastage

-

Safety hazards for operators

-

Emergency repair and replacement expenses

-

Reduced overall equipment lifespan

In high-pressure pump systems, internal wear and performance degradation often remain unnoticed without regular service, by the time a failure occurs, operational losses are already significant.

Why Industrial Pumps Need AMC-Based Support

Industrial pumps typically operate 24/7 under constant load and pressure. Over time, key components experience:

-

Internal wear and tear

-

Seal and bearing degradation

-

Calibration drift

-

Declining operational efficiency

Without a structured service plan, these gradual issues accumulate and result in major system failures. Annual Maintenance Contracts provide a disciplined, scheduled approach to maintaining pump performance and reliability.

With AMC vs Without AMC: The Difference That Matters

Without AMC

-

High risk of sudden breakdowns

-

Unplanned, reactive troubleshooting

-

Longer downtime and production disruption

-

Higher long-term operating and repair costs

With AMC

-

Scheduled inspections and routine servicing

-

Early identification of wear and performance deviations

-

Optimized efficiency and stable operation

-

Maximum uptime and system reliability

An AMC transforms maintenance from a reactive necessity into a controlled, value-driven operation.

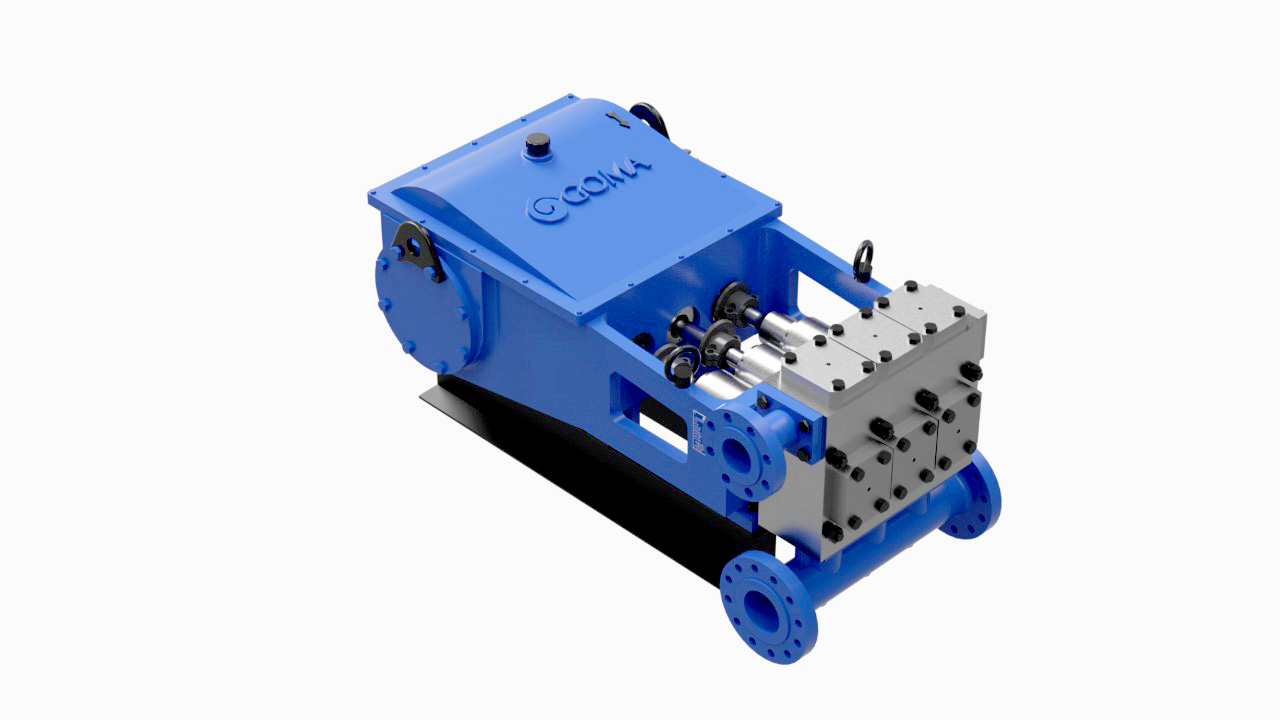

How Goma Pumps & Systems Supports Your Operations

At Goma, AMC and service support go beyond routine maintenance. With decades of expertise in high-pressure pumping systems, Goma ensures that critical equipment performs reliably throughout its lifecycle.

Goma Pumps & Systems provided AMC and service support for critical industrial applications, including oil & gas, paint manufacturing, steel processing, and metal powder industries, where equipment reliability and uptime are non-negotiable.

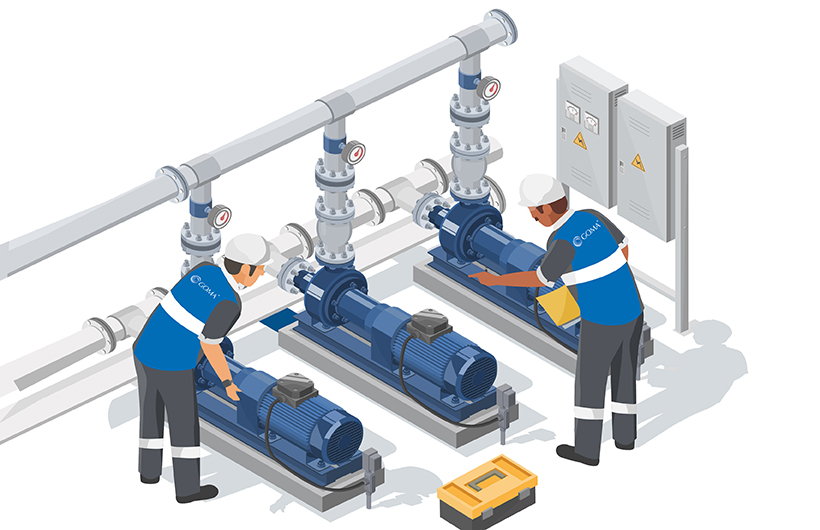

Comprehensive AMC & Service Support Includes:

Annual Maintenance Contracts (AMC)

Structured maintenance schedules designed to reduce operational risk and extend equipment life.

Commissioning & Remote Support

Technical assistance during installation, startup, and ongoing plant operations.

On-site & Virtual Troubleshooting

Quick resolution through experienced service engineers, both on-site and remote.

Genuine OEM Spare Parts

Ensuring compatibility, reliability, and long-term system integrity.

Overhauls & Calibration

Restoring pumps to optimal performance and maintaining process accuracy.

In today’s competitive industrial environment, uptime is more than a performance indicator, it’s a strategic advantage. Plants that operate under a structured AMC framework benefit from:

-

Higher equipment availability

-

Lower total cost of ownership

-

Improved safety and regulatory compliance

-

Consistent and predictable process output

With Goma’s AMC and service support, maintenance becomes planned, performance remains stable, and downtime is significantly reduced.

Your Uptime Is Our Priority

Industrial pumps operate under intense pressure—your maintenance strategy must be equally robust.

Partner with Goma to ensure your high-pressure pumps deliver reliable, efficient performance, day after day.