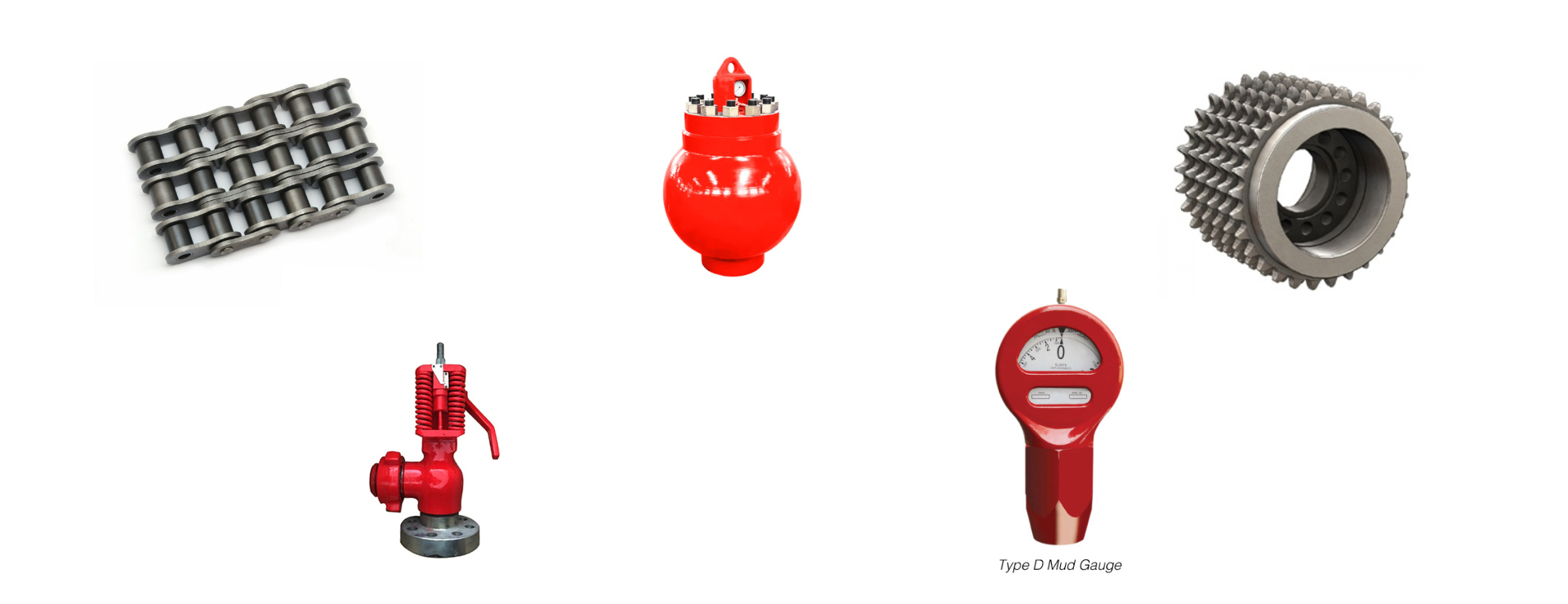

Mud pressure gauges play a crucial role in monitoring the pressure of drilling fluid within mud pumps, which is essential for safe and efficient operations. Built to handle high-pressure situations, they are made from robust materials that can endure tough conditions, provide shock resistance, and offer precise readings. Offered in both analog and digital formats, these gauges help avert equipment failures and enhance performance in drilling, mining, and construction activities.

Pulsation dampeners minimize pressure variations in mud pumps, promoting a steady flow of drilling fluid and safeguarding equipment against stress. Constructed from robust materials and innovative designs, they improve pump efficiency, decrease vibration, and prolong the lifespan of components. They come in either gas-charged bladder or piston configurations.

Mud pump chains and sprockets transfer power from the motor to the pump's power end, driving the reciprocating motion of the fluid end. They are essential for transmitting mechanical energy in the mud pump system. Based on customer requirement for pump speed and power rating, multiple chain sprockets options are available.

A safety relief valve, also known as a pressure relief valve, is an essential part of the mud pump system. It automatically opens to release excess pressure when it surpasses a set limit. This function helps prevent damage to the pump and related equipment, ensuring safe operation by managing system pressure.