Whether you’re setting up a small-scale mithai facility or expanding into industrial production, GOMA delivers complete support from concept to commissioning.

Functionality:

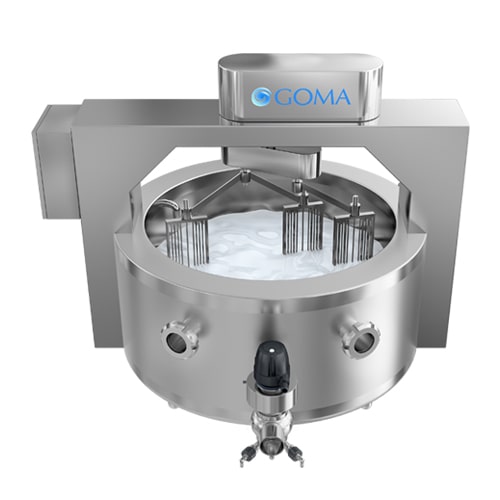

1)Produces fresh chenna from milk through controlled curdling.

2) Designed with variable capacity for artisanal or industrial scale.

3) Built in SS304/SS316 for hygienic operation.

4) Automated control panel for temperature and process monitoring.

Benefits:

1) Enables consistent production of paneer/chenna.

2) Forms the base for sweets like Rasgulla, Sandesh, and Rasmalai.

3) Ensures higher yield with minimal manual intervention.

Functionality:

1)Produces set curd for shrikhand and dahi under controlled conditions.

2) Equipped with whey removal and blending systems.

3) Constructed with food-grade stainless steel.

4) Integrated controls for temperature, agitation, and filling operations.

Benefits:

1) Maintains authentic taste and smooth texture.

2) Ensures hygienic and contamination-free production.

3) Facilitates continuous, large-scale shrikhand and dahi processing.

Enables bulk production of rich, dense milk-based sweets with consistent quality.

Supports soft-textured chenna sweet production with precise processing control.

Facilitates uniform frying and syrup absorption for traditional fried sweets.

Ensures hygienic fermentation and smooth texture in cultured milk products.

Adaptable for various textures and cooking methods in traditional dry sweets.

Supports scalable production of authentic, seasonal, and local sweet varieties.