Functionality:

1) Inline blending of sweeteners, fruit Flavors, and herbal concentrates

2) Flowmeter and load cell-based dosage control

3) PLC-based recipe programming

4) Homogeneous mixing with product clarity maintained

Benefits:

1) Customized flavour profiles

2) High precision in ingredient dosing

3) Flexible formulation options

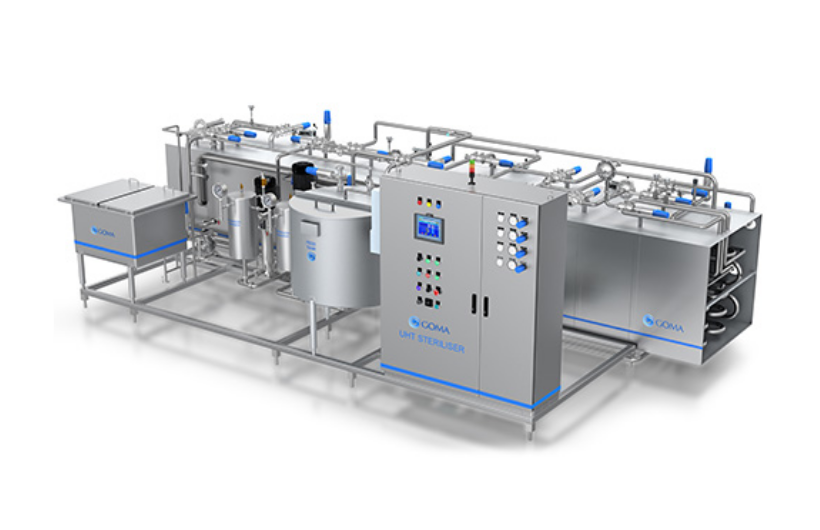

Functionality:

1) Heat treatment for microbial inactivation

2) Plate/tubular pasteurizers

3) Homogenizers for product stability

4) Suitable for both hot fill and aseptic applications

Benefits:

1) Enhanced shelf life

2) Product safety and compliance

3) Maintains natural flavour integrity

Functionality:

1) Hot fill or aseptic cold fill systems

2) Bottle, can, or PET pack compatibility

3) Automatic rinsing, filling, and capping

4) Volume-controlled dispensing

Benefits:

1) Long shelf-stable product

2) Tamper-proof packaging

3) Minimal product loss during filling

Functionality:

1) Automated cleaning of pipelines, tanks, and equipment

2) Multi-cycle cleaning for different production stages

3) Chemical dosing with temperature control

4) Validated sanitation process

Benefits:

1) Reduced downtime

2) Ensures hygiene compliance

3) Lowers manual labour costs

Classic formulations with consistent brewing and clarity.

Lemon, peach, mint, and other fruit/herbal variants.

Infused with natural extracts and wellness ingredients.

Customizable blending for various health-conscious markets.