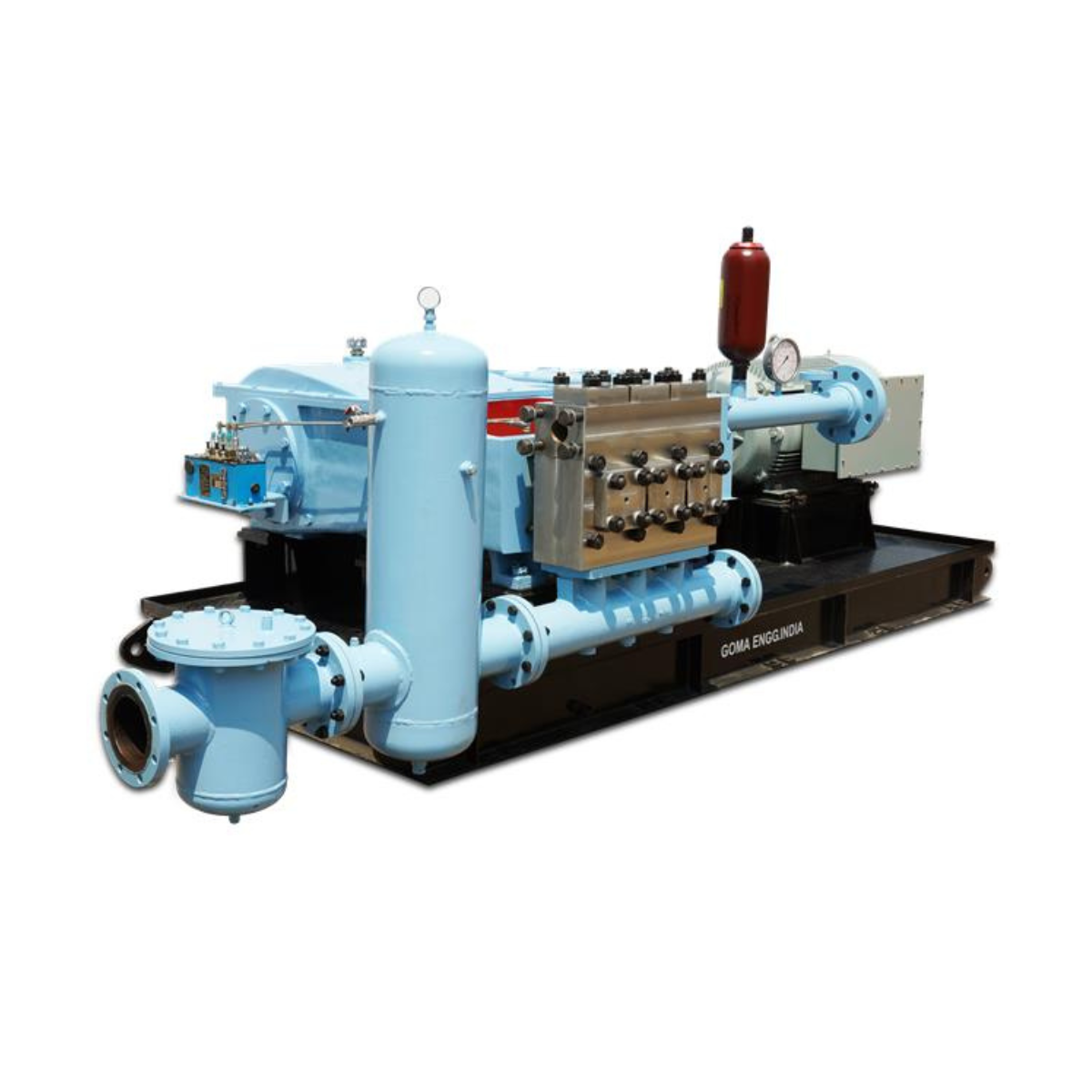

API 674 pumps are essential for reinjecting produced water and industrial effluents into reservoirs or disposal wells. They handle high pressures and are designed to manage corrosive fluids and suspended solids, supporting reservoir pressure maintenance, enhanced oil recovery (EOR), and environmental compliance.

These pumps are used to transfer crude oil from storage tanks to transport vehicles or pipelines. They are built to handle the high viscosity and abrasiveness of crude oil, ensuring consistent flow rates and reliability in oil dispatch operations.

API 674 pumps facilitate the loading and unloading of tankers with various liquids, including chemicals and fuels. They provide precise control of overflow rates and pressures during these processes, ensuring efficient and safe operations at terminals or industrial facilities.

Used for transferring condensate, a byproduct of natural gas processing or steam turbines. These pumps maintain necessary pressure and flow rates for downstream processes or re-injection, handling light hydrocarbon liquids with reliability.

Hot oil circulation is a process used in Enhanced Oil Recovery (EOR) to improve crude oil flow by reducing viscosity. It involves injecting heated oil or fluids into the well to dissolve blockages like wax or paraffin in the production tubing. By raising the temperature, viscosity decreases, facilitating oil flow to the surface.

API 674 pumps are designed to transfer collect and transfer slop, which includes oily residues and waste which spill over during pigging operations of pipelines. They handle abrasive and viscous fluids efficiently, ensuring effective treatment, disposal, or reprocessing while minimizing environmental impact.

API 674 pumps are used to inject methanol and glycol into pipelines to prevent hydrate formation and ensure flow assurance in oil and gas production. They deliver chemicals at high pressures to protect pipeline integrity and maintain safe operations.

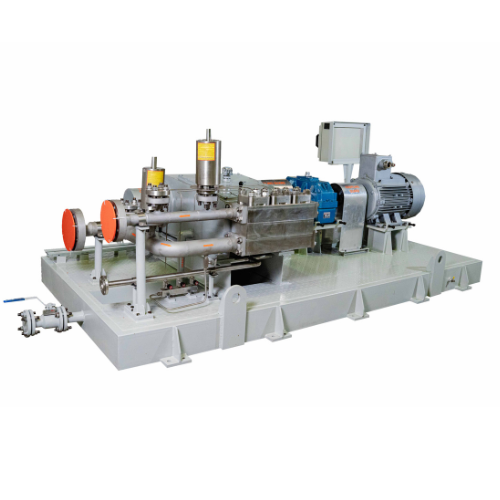

Pumps used for injecting polymers into oil and gas wells or for water treatment. They manage varying viscosities and concentrations of polymers, providing precise flow rates under high pressures for enhanced oil recovery or water treatment.

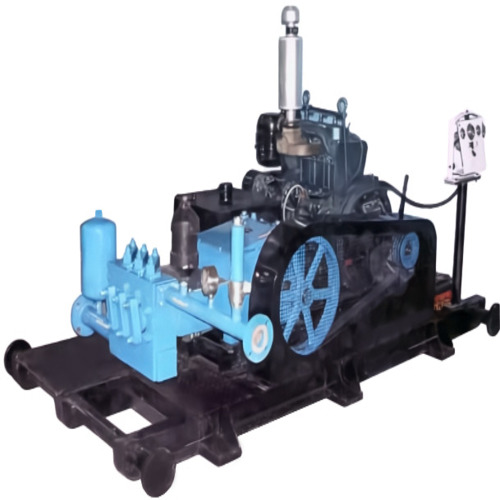

Pumps mounted on trucks for portable applications in emergencies, temporary operations, or remote locations. They are designed for flexibility and reliability in dynamic environments, supporting rapid deployment and effective fluid handling.

Wash water injection pumps in refineries remove salts and contaminants from process streams, protecting equipment and enhancing efficiency. Operating at high pressures, these pumps prevent corrosion and fouling in downstream units.

BOP Charging Pumps:

These pumps charge Blowout Preventer (BOP) systems with hydraulic fluids necessary for operation. They ensure reliable hydraulic pressure to the BOP systems, which are crucial for well control and safety during drilling operations.

Applications in Fertilizer Industry

Ammonia Pumps:

Ammonia pumps are designed to handle and transfer ammonia in its liquid form. These pumps are engineered to accommodate the unique properties of ammonia, such as its corrosiveness and high-pressure requirements. They play a crucial role in the fertilizer industry by moving ammonia from storage to different stages of the production process.

Carbamate Pumps:

These Pumps are specifically designed for the transfer and handling of carbamate solutions, carbamate pumps are engineered to manage the chemical's high pressure, temperature, and corrosive properties. Carbamate is an intermediate compound in the urea production process, formed by the reaction of ammonia with carbon dioxide.

Borated Water Pumps:

Borated water pumps are high-pressure pumps used in nuclear reactors to inject borated water into the primary coolant loop. This borated water plays a crucial role in cooling the reactor core by transferring heat to a secondary circuit. Additionally, boron acts as a neutron absorber, helping to control reactivity and regulate the rate of fission within the reactor.

Fuelling Machine Supplying Pumps:

Fuelling machine supply pumps are specialized pumps in nuclear power plants that provide coolant or hydraulic fluid to the fuelling machine during refuelling. They facilitate the handling and insertion of uranium fuel rods or assemblies into the reactor core by ensuring the efficient operation of the fuelling machine's mechanical systems, such as cranes and manipulators. This process guarantees safe and precise fuel loading operations.