Functionality:

1) Uniformly blends malt extract, water, sugar syrup, and micronutrients

2) Equipped with high-efficiency agitators

3) Jacketed design for heating or cooling if needed

4) Controlled via PLC panel

Benefits:

1) Delivers a consistent product base

2) Prevents ingredient separation

3) Enables precise recipe customization

Functionality:

1) Reduces particle size for smooth texture

2) Increases product stability and shelf life

3) Continuous inline operation for efficiency

4) Easy-to-clean design

Benefits:

1) Creates uniform mouthfeel

2) Prevents sedimentation

3) Enhances drink quality and appearance

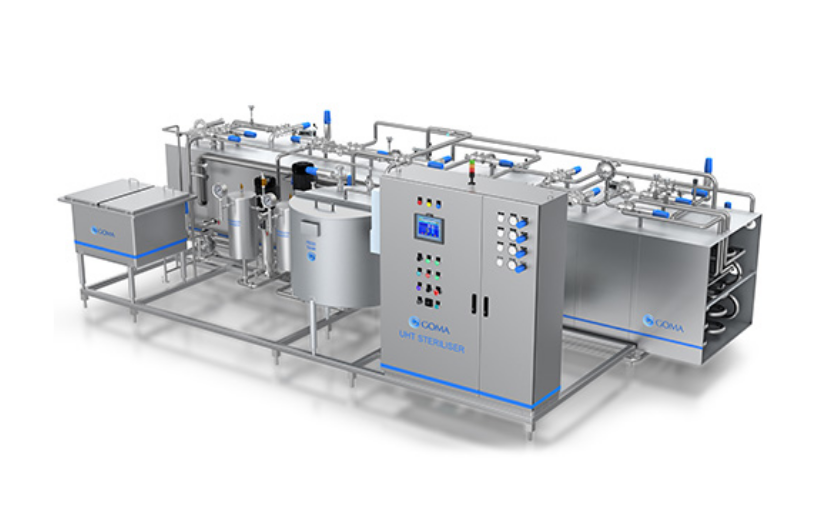

Functionality:

1) Heat treats the product to kill pathogens

2) Offers temperature and holding time control

3) Available as plate, tubular, or coil type

4) Fully automated control system

Benefits:

1) Ensures product safety and compliance

2) Extends shelf life without preservatives

3) Maintains taste and nutritional quality

Functionality:

1) Reduces product temperature post-pasteurization

2) Works with chilled water or glycol

3) Ensures product enters filling zone at safe temp

4) Compact, energy-efficient unit

Benefits:

1) Preserves taste and nutrients

2) Prevents post-process contamination

3) Minimizes wait time before packaging

Functionality:

1) Accurately fills into bottles, pouches, or jars

2) Hygienic contact parts with quick changeover

3) Seals containers using heat or pressure sealing

4) Available in multiple speed and size configurations

Benefits:

1) Versatile for different packaging needs

2) Maintains hygiene during filling

3) Suitable for pilot and commercial operations

Functionality:

1) Automated cleaning-in-place for tanks and pipelines

2) Uses pre-programmed cycles with hot water and chemicals

3) Reduces manual cleaning effort

4) PLC-based control for consistency

Benefits:

1) Saves time and labor

2) Improves plant hygiene and compliance

3) Minimizes production downtime

Milk-based drinks for children

Infused with added nutrients or herbs

For vegan or lactose-intolerant consumers

Ideal for fitness and sports nutrition