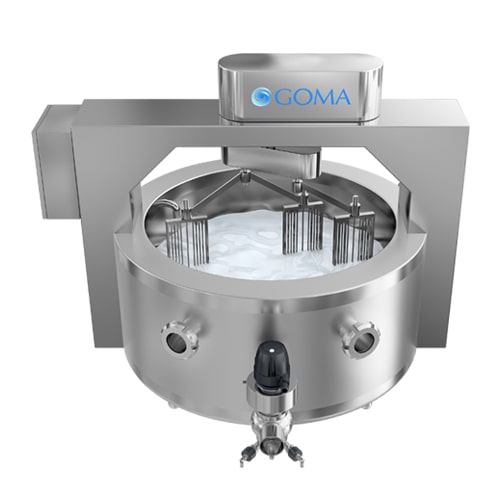

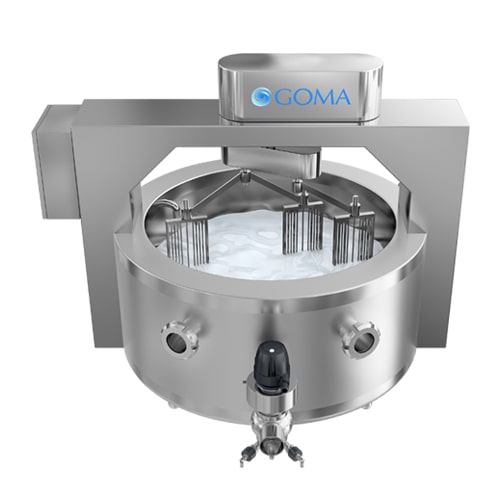

Cheese & Paneer Vat

A synchronized Cheese/ Paneer Vat built by Goma Engineering from hybrid technology to fasten the processing speed in the manufacturing sector with the highest efficiency.

Large-scale paneer block production

Controlled curdling, pressing, and shredding.

European-style cheese fermentation.

Processing of mold-ripened and stretched-curd cheeses.