Beverages (33).png)

Functionality:

1) Blends malt extract with water, sugar syrup, and additives

2) Agitator system for uniform mixing

3) SS 304/316L construction

4) PLC or manual operation

Benefits:

1) Ensures formulation consistency

2) Hygienic and easy to clean

3) Compatible with heat-sensitive ingredients

Functionality:

1) Breaks particles into micro-size

2) Improves emulsion stability

3) Stainless steel body with CIP-ready design

4) Adjustable speed and pressure

Benefits:

1) Enhances product texture

2) Prevents separation during storage

3) Improves shelf-life stability

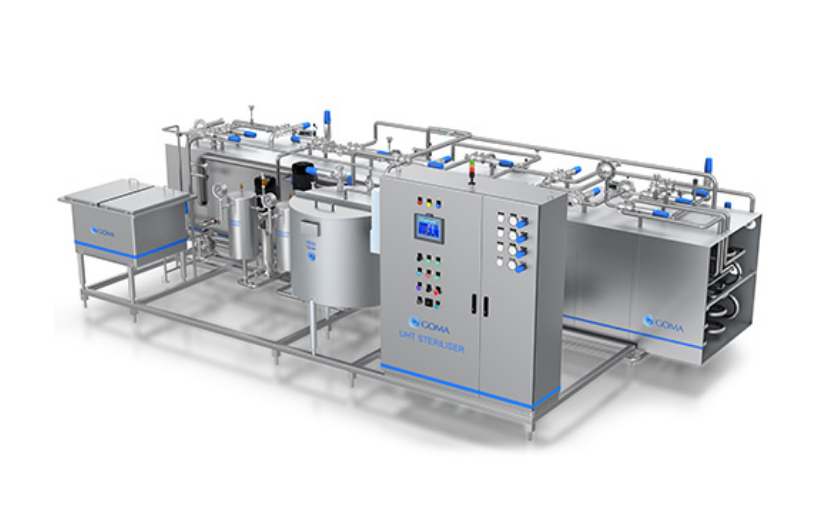

Functionality:

1) Kills harmful microbes

2) Plate or tubular heat exchanger options

3) PID-controlled temperature regulation

4) Fully automated with data logging

Benefits:

1) Ensures food safety

2) Prolongs product shelf life

3) Maintains flavor and nutritional value

Functionality:

1) Fills bottles, pouches, or jars

2) SS contact parts for hygiene

3) Optional nitrogen flushing

4) Auto or semi-auto depending on scale

Benefits:

1) Versatile packaging formats

2) Clean and consistent fill levels

3) Scalable for startups to large units

Functionality:

1) Automated cleaning of tanks and lines

2) Programmable detergent cycles

3) SS piping and control panel

4) Zero product contamination

Benefits:

1) Minimizes manual labor

2) Ensures food-safe operations

3) Speeds up changeover time

Milk-based drinks for children

Infused with added nutrients or herbs

For vegan or lactose-intolerant consumers

Ideal for fitness and sports nutrition