Spray drying is a highly effective way to transform liquid materials into stable, easy-to-handle powders that can be stored for a long time. GOMA Engineering offers fully integrated spray drying and powder plant solutions for the dairy, food, pharmaceutical, and chemical industries. Our systems are designed for precision, hygiene, and scalability—featuring modular layouts and automation to meet the demands of both small-scale operations and high-capacity commercial plants.

With over four decades of experience in process engineering, GOMA supports customers with turnkey powder processing lines—from feed preparation and evaporation to drying and powder sifting. Each system is built using food-grade SS304/SS316 materials and is equipped with automation-ready controls and PLC panel, ensuring consistent product quality, operational hygiene, energy efficiency, and full compliance with international standards.

Functionality:

1) Ensures uniform particle size in liquid feed.

2) Operates at high pressure for stable emulsions.

3) Built with food-grade SS construction.

4) CIP-compatible and suitable for continuous duty.

Benefits:

1) Enhances powder consistency and solubility.

2) Prevents separation during drying.

3) Improves overall product shelf life.

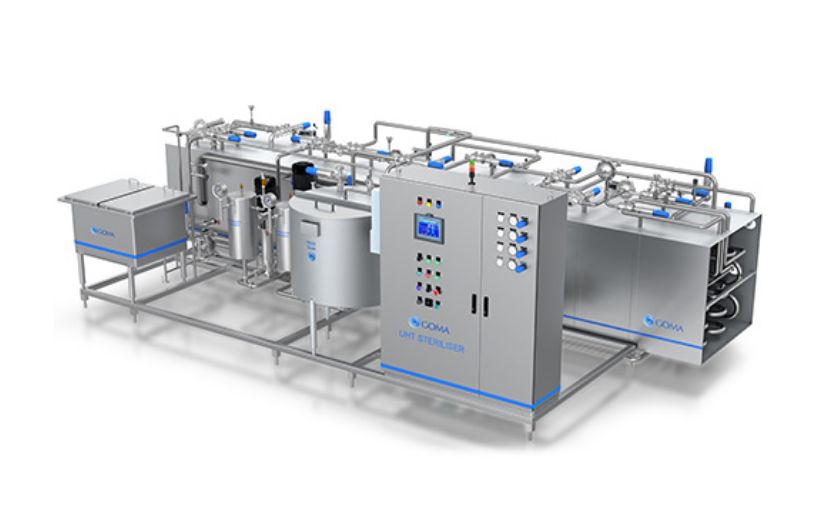

Functionality:

1) Heat-treats feed to eliminate microbial load.

2) Suitable for dairy, food, and pharma inputs.

3) Compact, skid-mounted stainless-steel design.

4) Integrated with precise thermal controls and safety features.

Benefits:

1) Ensures product safety and regulatory compliance.

2) Maintains quality of heat-sensitive materials.

3) Extends powder shelf stability.

Functionality:

1) Automated Cleaning-In-Place system for tanks, pipelines, and equipment.

2) Integrated with PLC control for sequence automation.

3) Includes dosing pumps, holding tank, valves, and piping.

4) Monitors cleaning parameters with safety interlocks.

Benefits:

1) Reduces manual cleaning efforts and time.

2) Enhances hygiene and product safety.

3) Increases equipment availability and uptime.

Ideal for producing milk powder, whey powder, infant formula, spice extracts, and instant drink mixes.

Effective for pigments, catalysts, detergent bases, and agrochemicals requiring uniform dispersion.

Supports drying of probiotics, enzymes, and protein concentrates while retaining bioactivity.

Used in metallurgy and 3D printing applications requiring precise density and moisture control.