Functionality:

1) Produces 65–70° Brix syrup

2) Filters syrup and cools before storage.

3) Prepares syrup for blending on-demand

4) Includes jacketed tank, filter, and cooling system

Benefits:

1) Delivers consistent syrup quality

2) Reduces sugar crystallization

3) Supports quick switchovers for flavor variants

Functionality:

1) Blends syrup, pulp, RO water, and additives

2) Prevents separation with constant agitation

3) Integrated with homogenizer for uniformity and proper mixing

4) Output stored in insulated blending tanks

Benefits:

1) Ensures recipe consistency across batches

2) Enhances shelf life and flavour stability

3) Handles natural and synthetic formulations

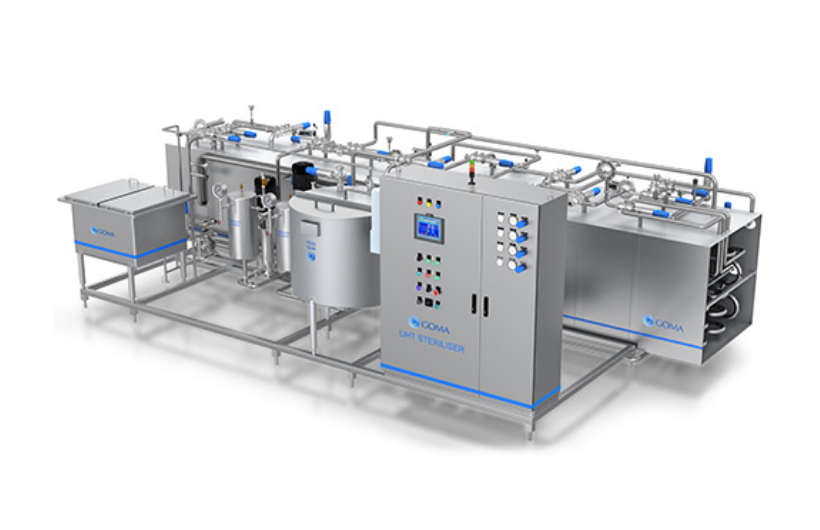

Functionality:

1) Uses plate/tubular heat exchangers

2) Heats up to 90°C for microbial deactivation

3) Supports both hot-fill and cold-fill systems

4) Connected to filler lines

Benefits:

1) Increases product safety and shelf life

2) Suitable for pulp-rich and fiber-based drinks

3) Rapid and controlled thermal treatment

Functionality:

1) Compatible with PET, HDPE, Glass, Tin or brick packs

2) Temperature-controlled filling based on product type

3) Options include rotary, volumetric, and gravity fillers

4) Integrated with cappers, labelers, and shrink tunnels

Benefits:

1) Maintains hygiene and filling accuracy

2) Offers flexibility in packaging SKUs

3) Reduces operational downtime

Functionality:

1) Automatic or semi-automatic tank-based CIP

2) Includes acid, alkali, hot water tanks, and pumps

3) Controlled via PLC panel for programmable cycles

4) Available in trolley-based or fixed formats

Benefits:

1) Maintains hygiene without disassembly.

2) Speeds up batch transitions

3) Reduces water and chemical usage

Mango, guava, passionfruit, and synthetic juices prepared for ambient or chilled storage in PET or brick packs.

Flavored fizzy drinks created with precision-blended syrups and pressurized CO₂ systems for mass-market bottling.

A fusion of pulp, juice, and fizz delivering fruit-rich sparkling beverages that appeal to health-conscious consumers.