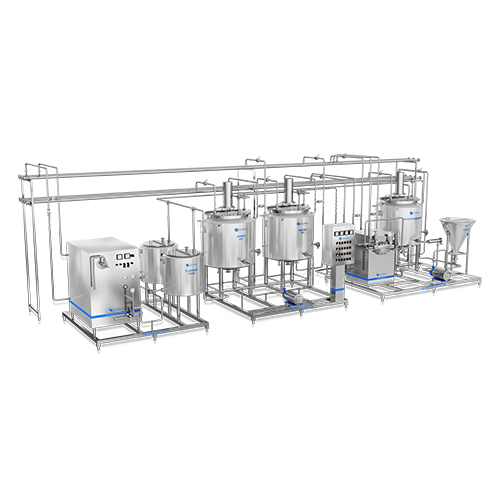

1) Functionality: Heats the ice cream mix to 65–85 °C, then cools it rapidly to 4 °C.

2) Capacity: 50–200 liters per batch (customizable).

3) Construction: Double-jacketed stainless steel tank with agitator and temperature control.

4) Control Panel: PLC or PID-based digital interface for precise temperature and time settings.

Benefits:

1) Eliminates pathogens and ensures food safety.

2) Improves ingredient dispersion, especially for stabilizers and emulsifiers.

3) Essential for both dairy and non-dairy formulations.

Refines fat globule size to improve creaminess, stability, and mouthfeel.

1) Pressure Range: 100–250 bar.

2) Capacity: 100–300 litres/hour.

3) Construction: Stainless steel high-pressure pump with adjustable valve.

4) Operation: Two-stage homogenization for optimal fat distribution.

Benefits:

1) Enhances texture and overrun control.

2) Prevents fat separation in storage.

3) Increases stability for longer shelf life.

Holds mix at low temperatures to allow hydration and fat crystallisation.

1) Temperature Range: 2–4 °C (chilled using integrated or external chiller).

2) Capacity: 100–200 liters.

3) Construction: Insulated SS316 tank with slow-speed agitator.

4) Time Range: 4–24 hours.

Benefits:

1) Improves whipping properties.

2) Enhances body and texture of ice cream.

3) Stabilizers and emulsifiers perform best after aging.

Rapidly chill the mix post-pasteurisation to prepare for freezing.

1) Cooling Media: Chilled water or glycol-based coolant.

2) Capacity: 100–500 litres/hour.

3) Plate Material: SS316L, food-grade gasketed plates.

4) Temperature Drop: From 80–85 °C to 4–5 °C within seconds.

Benefits:

1) Minimizes microbial growth risk.

2) Retains flavor and color integrity.

3) Improves process efficiency.

Freezes and aerates the mix, controlling overrun and texture.

Freezing Capacity:

1) Batch: 10–50 liters/cycle.

2) Continuous: 100–500 liters/hour.

3) Overrun Control: Adjustable from 20% to 100%+.

4) Freezing Medium: Ammonia or freon-based refrigeration.

5) Construction: Stainless steel barrel, dasher, and beater with auto-scrapers.

Benefits:

1) Produces consistent and smooth ice cream.

2) Air incorporation (overrun) is easily adjustable.

3) Suitable for all frozen dessert categories.

Automates internal cleaning cycles for hygiene and compliance.

2) Pump Type: Sanitary centrifugal pump with high-pressure spray balls.

3) Temperature Control: 60–85 °C cleaning cycles.

4) Capacity: 100–200 liters per tank.

Benefits:

1) Reduces downtime between batches.

2) Ensures compliance with hygiene and safety standards.

3) Minimises manual cleaning labor and risk of contamination.

Classic, premium, or customized dairy-based flavors with controlled texture and overrun.

Almond, oat, soy, or coconut-based frozen desserts for health-conscious or lactose-free markets.

Dense, low-air frozen treats with traditional or exotic flavor profiles.

Fruity, dairy-free alternatives ideal for vegan or allergen-free offerings.

Protein-fortified, vitamin-enriched, or low-sugar formulations targeting wellness segments.