24 August 2024

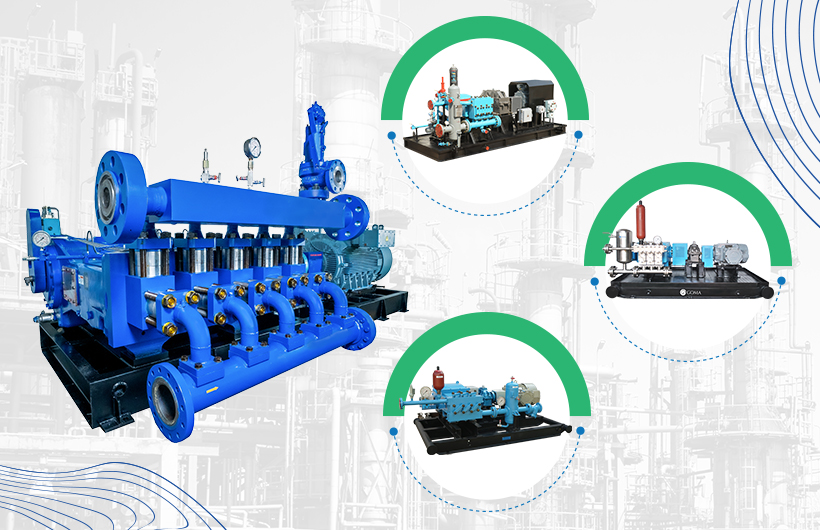

Understanding API 674 Reciprocating Pumps

Among industrial pumping solutions, reciprocating pumps labelled with API 674 have become widely popular due to their reliability and adaptability in demanding applications. These pumps are designed to operate under high pressure and high-performance conditions, meeting the rigorous standards set by the American Petroleum Institute. The API 674 designation defines the design, material, and performance requirements of reciprocating positive displacement pumps utilized in the petroleum, petrochemical, and natural gas industries. The pump's use encompasses dealing with a wide range of fluids under high pressure, making it suitable for critical applications.

What is API 674 Reciprocating Pump?

API 674 is a standard established by the American Petroleum Institute detailing the design, material, and performance requirements for reciprocating positive displacement pumps. Reciprocating Pump is essential in the petroleum, petrochemical, and natural gas industries for effectively and reliably handling high-pressure fluids.

Key Features of GOMA’s API 674 Reciprocating Pumps

Crankcase: Manufactured from high-quality cast iron, the crankcase is engineered to withstand maximum load capacity. For higher models, an open-top design allows for easier maintenance and reassembly.

Crankshaft: Crafted from high carbon or alloy steel, the crankshaft exhibits hardened toughness and a high endurance limit. It comes with ground crank pins and two roller/taper bearings for support. Most models offer reversible power frames for flexibility in driving input.

Crosshead with Extension Rod: Constructed from SG iron with a machined and ground surface. The extension rod is chrome-plated to resist corrosion and wear.

Connecting Rod: A sturdy SG Iron casting with separate bolted caps, featuring split antifriction steel bearings with Babbitt-lined inner surfaces.

Oil Seal Retainer: Contains the oil seals for the extension rod of the crossheads and is easily removable for maintenance.

Suction/Discharge Assembly: Showcasing press-fitted valve assemblies with various valve types (plate, ball, wing) and valve seat options based on liquid properties.

Stuffing Box: Developed from stainless steel or carbon steel, depending on the application and liquid. It incorporates several types of plunger seals, space rings, lantern rings, and grid bushings.

Pump Speed: Reduced wear and tear due to adherence to maximum allowable speed rating of API-674

Application of Goma’s High-Pressure API 674 Pumps in the Oil and Gas Industry

The API 674 Reciprocating pumps are critical in handling high-pressure fluids with precision and reliability. Their robust design and high performance make them ideal for various applications in the oil and gas industry, including:

-

Salt Water / Effluent Water injection Pumps:

Water injection involves the injection of water into the oil field, usually to increase pressure and thereby stimulate production. Water injection wells can be found both onshore and offshore to enhance oil recovery from an existing reservoir.

-

Crude Oil Start Up/ Dispatch (COD) Pumps:

CODP are utilized to transport crude oil from the wellhead to gathering and processing facilities and from there to refineries & tanker loading facilities. Also used for restart rocking & slop transfer applications at pump stations.

-

Condensate Transfer Pumps:

Hydrocarbon condensate is transferred from HP/LP flare knockout drums or hazardous effluents from a closed drain tank. Fluids are collected from various sources before transfer back to the main process for recovery and disposal.

-

Wash water injection:

In refineries, our pumps are utilized to absorb and prevent the loss of amine vapors; pumps are specially designed with a pot seal design for the stuffing box to trap the leakage of gases.

-

Hot oil Circulation (HOC):

Refineries use pumps to handle hydrocarbons at low flow rates and pressures up to 4000PSI and high temperatures up to 700 F. These pumps are specially designed to handle high-temperature fluids.

-

Methanol and Glycol (MEG) Injection Pumps:

Methanol and glycol injection pumps are employed in process lines where there is a risk of hydrate formation at low temperatures. High Pressure Pump are required to overcome friction losses in subsea pipelines where the wellhead can be up to 100 kms from the platform.

At Goma, we incorporate API 674 standards into our high-pressure pump solutions, providing reliability and performance across various applications. Whether it is oil extraction, chemical processing, or water treatment, Goma's API 674 pumps are designed to meet the highest standards of efficiency and safety. Understanding the capabilities and advantages of API 674 pumps will aid in selecting the right pumping solutions for your needs, ensuring operational excellence and innovation across various industries.