19 November 2025

Turnkey Food & Beverage Processing Solutions: Why Businesses Trust GOMA for End-to-End Execution

In today’s highly competitive food and beverage market, manufacturers require more than just individual equipment they need complete turnkey solutions that ensure seamless integration, higher efficiency, and consistent product quality. From milk and beverages to non-dairy and specialty liquid products, turnkey execution has become the benchmark for reliability, scalability, and return on investment.

At the forefront of this transformation is GOMA Process Technology & Equipment Pvt. Ltd., a leading name in Process Technology & Equipment Manufacturing, delivering comprehensive, end-to-end turnkey projects for the dairy, beverage, and food processing industries.

Comprehensive Turnkey Expertise

GOMA provides an integrated approach from design conceptualization to commissioning ensuring every stage of production is seamlessly aligned.

Key Turnkey Capabilities

-

Project Design & Engineering: In-house mechanical, process, and automation experts ensure precise plant layout, capacity optimization, and hygienic design compliance.

-

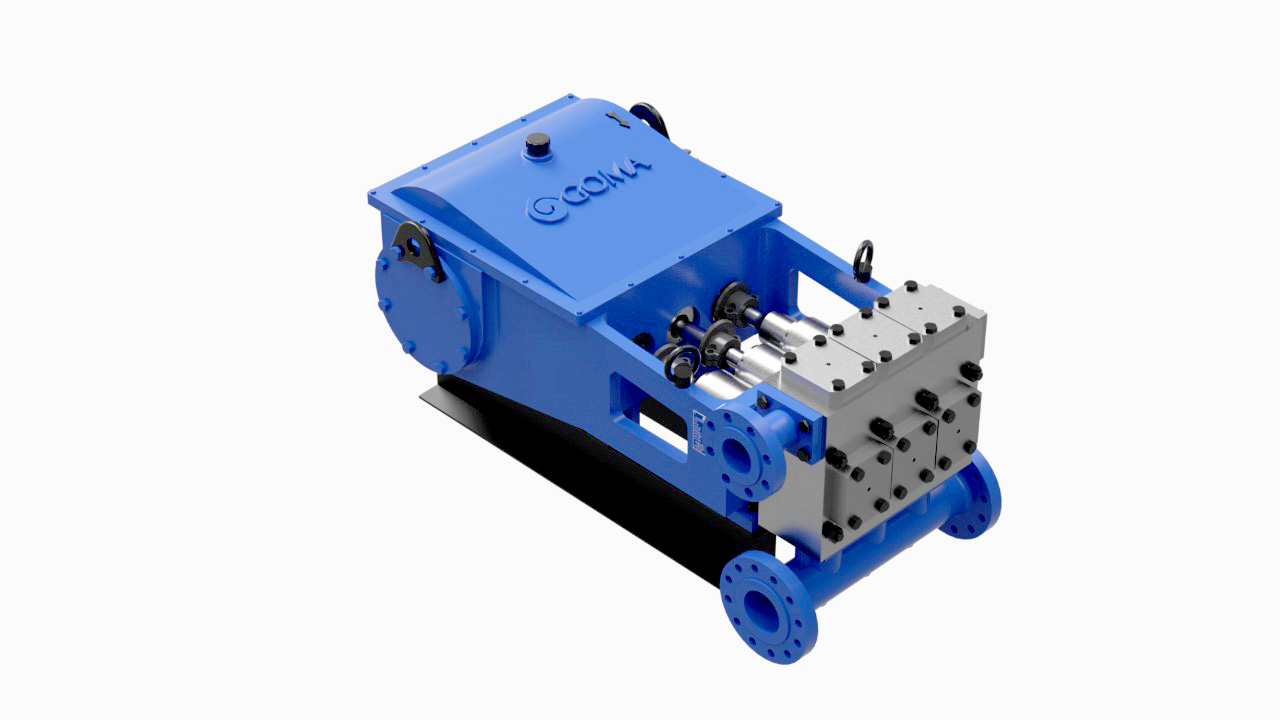

Equipment Manufacturing: Advanced in-house fabrication units deliver a full range of process equipment pasteurizers, homogenizers, UHT systems, mixing vessels, CIP systems, and aseptic fillers.

-

Automation & Control Systems: SCADA and PLC-based automation for process control, data logging, and digital traceability.

-

Installation, Commissioning & Validation: GOMA’s expert teams oversee on-site installation, testing, and validation to ensure process integrity and operational efficiency.

Why Businesses Choose GOMA

-

End-to-End Execution Under One Roof - From utility systems and process design to automation and packaging integration, GOMA ensures single-point accountability for the entire project reducing coordination delays and ensuring faster go-to-market timelines.

-

Proven Engineering Excellence - With over 40+ years of process experience, GOMA’s solutions are built on deep application expertise and global engineering standards, ensuring reliability, safety, and efficiency at every step.

-

Scalable and Custom-Built Solutions - Every plant is designed around specific product requirements whether it’s dairy, fruit beverages, protein-based drinks, or non-dairy alternatives allowing clients to scale capacity seamlessly with market growth.

-

Focus on Efficiency and Sustainability - GOMA integrates energy-efficient heat exchangers, water-saving CIP systems, and automated process control to minimize operating costs and environmental footprint while maintaining consistent product quality.

-

After-Sales Support and Lifecycle Service - Dedicated O&M contracts, preventive maintenance programs, and technical training ensure long-term plant reliability and reduced downtime.

Industries Served

-

Dairy Processing: Milk, cream, butter, ghee, yoghurt, and UHT milk plants

-

Beverage Processing: Fruit drinks, juices, flavored milk, and energy drinks

-

Non-Dairy Processing: Plant-based beverages, nutraceuticals, and specialty liquid foods

-

Custom Process Systems: CIP skids, high-pressure pumps, and aseptic lines for pharma and biotech applications

The GOMA Advantage

-

Single-source turnkey responsibility

-

In-house design, fabrication, and automation

-

Faster project delivery and validation

-

Regulatory compliance with FSSAI, GMP & EHEDG

-

Reliable after-sales and technical service support

Turnkey food and beverage processing is no longer a convenience it is a strategic imperative for quality, efficiency, and scalability. With GOMA’s engineering depth, manufacturing excellence, and execution expertise, clients gain a trusted partner who delivers not just plants, but performance-driven results.

GOMA continues to empower food and beverage manufacturers across India and beyond transforming process ideas into efficient, sustainable, and fully operational facilities.