17 September 2025

Can Automation Really Replace Manual Expertise in Dairy Plants?

Walk into any modern dairy plant today, and you’ll notice a shift. Stainless steel pipelines, touch-screen panels, automated filling lines — machines are taking over jobs that once relied purely on skilled hands. But here’s the real question: can automation truly replace manual expertise in dairy processing, or do we still need the human touch?

Why Automation is Changing the Dairy Industry

Consistency You Can Trust

Producing thousands of liters of milk or yoghurt every day while maintaining the same taste, texture, and safety across every batch is no easy feat. Automation makes this possible. Pasteurizers, homogenizers, and separators operate with ±0.1°C precision, something no human can consistently achieve.

Speed and Productivity

A manual line might process around 2,000–3,000 liters/hour. Automated plants, by contrast, can handle 20,000–50,000 liters/hour — without increasing manpower. Packaging machines running at 98% efficiency ensure plants keep up with growing demand and minimize downtime.

Saving Energy and Resources

Automation isn’t just about speed. Intelligent controls reduce steam usage by up to 20% and save 10–15% water during CIP (Clean-in-Place) cycles. Energy-efficient drives and motors also help cut power consumption by 8–12%, making plants both productive and sustainable.

Where Automation Still Falls Short

Even the most advanced machines cannot replace human expertise entirely. Skilled technologists remain essential for:

-

Adjusting recipes for local taste preferences.

-

Troubleshooting unexpected issues.

-

Ensuring compliance with strict quality and safety standards.

Automation also comes with significant capital costs, with ROI typically realized over 3–5 years, depending on plant scale.

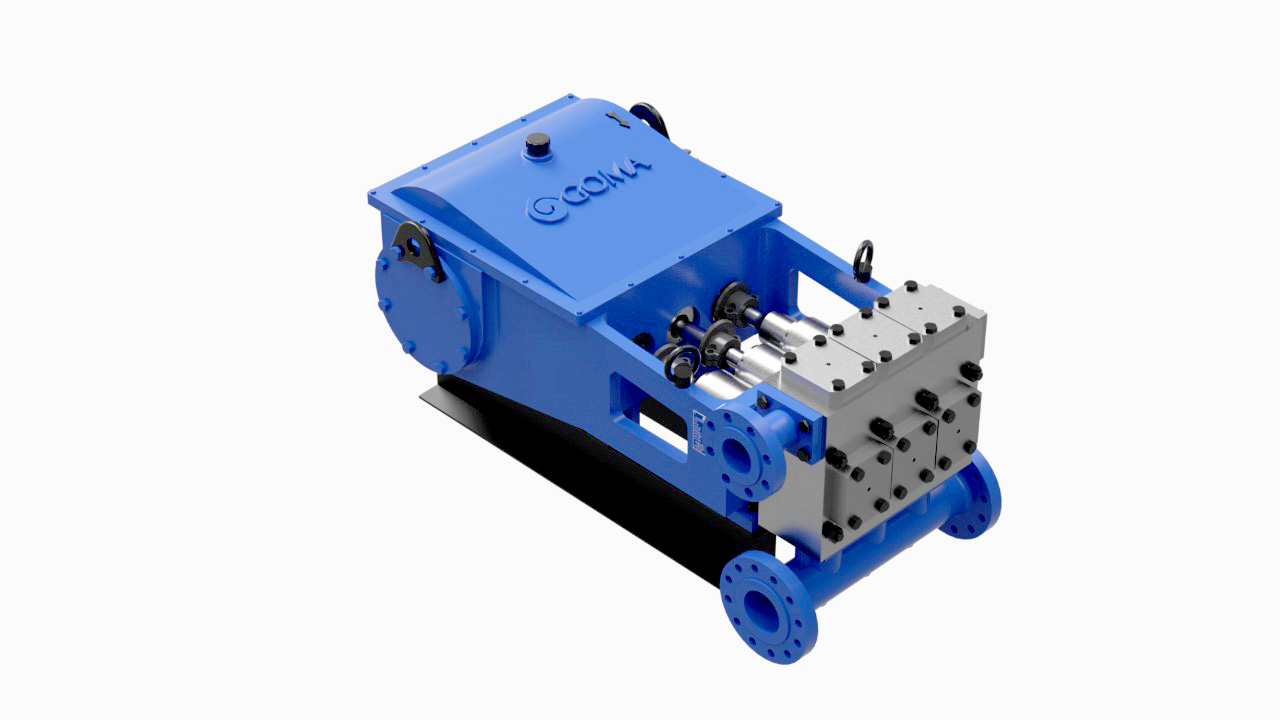

GOMA Automation Solutions: Technology That Works

Automation works best when combined with practical expertise. GOMA designs its systems to deliver efficiency, hygiene, and consistent quality, while empowering operators to focus on innovation and oversight.

-

Pasteurizers – Capacities from 500 to 20,000 LPH, providing precise temperature control for milk, yoghurt, and other dairy products while ensuring safety with minimal operator intervention.

-

Homogenizers – Operating at 100–400 bar, delivering smooth textures, stable emulsions, and uniform product quality batch after batch.

-

CIP Systems – Fully automated cleaning with >99% efficiency, optimizing water, steam, and chemical usage, while reducing downtime.

-

Filling & Packaging Solutions – Servo-driven machines handling 5,000–30,000 packs/hour, adaptable to bottles, pouches, cups, and cartons, with minimal wastage.

-

Sanitary Pumps – Hygienic and gentle product transfer that preserves quality and ensures reliable flow throughout the processing line.

The result? Dairy plants that are smarter, more productive, and fully aligned with modern hygiene and safety expectations.

The Balanced Future: Automation + Expertise

Can automation replace manual expertise? Not entirely. Machines excel at repetitive, high-volume tasks with unmatched precision, but the knowledge, creativity, and problem-solving of dairy experts remain irreplaceable.

The future lies in the perfect synergy of both — automation for consistency and efficiency, and humans for innovation, oversight, and quality assurance. That’s the model GOMA is helping dairies implement today.