08 November 2024

Understanding the Process of Milk Pasteurization: What You Need to Know with GOMA

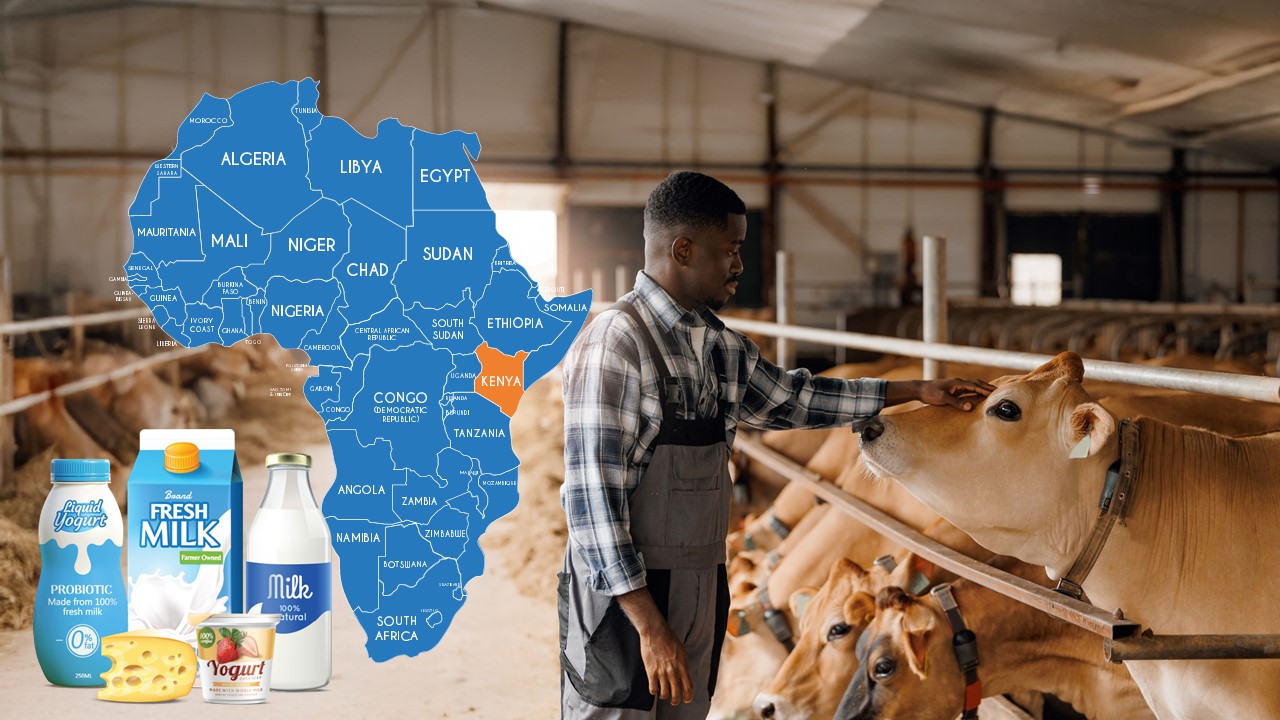

Milk pasteurization is an essential procedure in the dairy industry aimed at ensuring the safety and quality of milk and dairy products. Named after the French scientist Louis Pasteur, who pioneered the method in the 19th century, pasteurization has become a standard practice that effectively eliminates harmful microorganisms while maintaining the nutritional value of milk. At GOMA, we are dedicated to offering advanced dairy processing solutions that support this vital process. Here’s a detailed overview of the pasteurization process, its significance, and key information you should know.

What is Pasteurization?

Pasteurization involves heating milk to a specific temperature for a designated time and then quickly cooling it down. This process effectively destroys pathogenic bacteria, yeasts, and Molds that can lead to spoilage and illness, all while preserving the milk's flavour and nutritional content.

The Pasteurization Process

-

Preparation: Fresh milk is sourced from local dairy farms and transported to nearby processing facilities in refrigerated trucks to keep it fresh. Upon arrival, the milk undergoes rigorous quality checks to ensure it is free from contaminants. This includes testing for antibiotic residues counts to meet the highest quality and safety standards. Once it passes these checks, the milk is ready for pasteurization to further ensure its safety for consumption.

Heating: The milk is warmed to a particular temperature.

Batch Pasteurization: Milk is heated to 145°F (65°C) for 30 minutes. This traditional method is less commonly used today but is preferred for certain artisanal products.

High-Temperature Short-Time (HTST): Milk is heated to about 176°F (80°C) for 20 seconds. This method is the most widely used for commercial milk.

High-Temperature High Time (HTHT): Milk is heated to around 194°F (90°C) for 10 minutes.

Ultra-High temperature (UHT): Milk is heated to 280°F (138°C) for at least 2 seconds, extending its shelf life significantly, often up to several months without refrigeration.

-

Cooling: After the milk is heated, it is quickly cooled to below 40°F (4°C) to stop any remaining bacteria from growing. This quick cooling step is essential for keeping the milk fresh and of high quality.

-

Storage and Packaging: The pasteurized milk is kept in sanitized containers and packaged for distribution. Some milk may also go through additional processes, like homogenization, to ensure a consistent texture and prevent the cream from separating.

Importance of Pasteurization

• Food Safety: Pasteurizer greatly lowers the risk of foodborne illnesses caused by pathogens such as Salmonella, E. coli, and Listeria. It makes milk safer to drink, particularly for vulnerable groups like children and the elderly.

• Extended Shelf Life: By eliminating spoilage-causing microorganisms, pasteurized milk lasts longer than raw milk. This helps minimize waste and allows consumers to enjoy fresh dairy products for a more extended period.

• Preservation of Nutritional Quality: While pasteurization kills harmful bacteria, it also keeps most of the essential nutrients in milk, including vitamins, minerals, and proteins. Research indicates that pasteurized milk offers similar nutritional benefits to raw milk, making it a healthy option.

The Role of GOMA in Pasteurization

At GOMA, we focus on creating advanced Dairy processing equipment that enhances the pasteurization process. Our systems provide precise temperature control and effective cooling, ensuring both safety and quality. We are dedicated to supporting dairy producers in providing safe, high-quality products to consumers.

Understanding the pasteurization process is essential for anyone involved in the Dairy industry or interested in Dairy consumption. At GOMA, we focus on delivering cutting-edge Milk process equipment and solutions that guarantee efficient and effective pasteurization. This process is key to removing harmful microorganisms and prolonging shelf life, ensuring that milk remains safe and nutritious. By adopting this essential method, consumers can confidently enjoy the numerous advantages of dairy products, assured that they are making safe and healthy choices.