11 July 2025

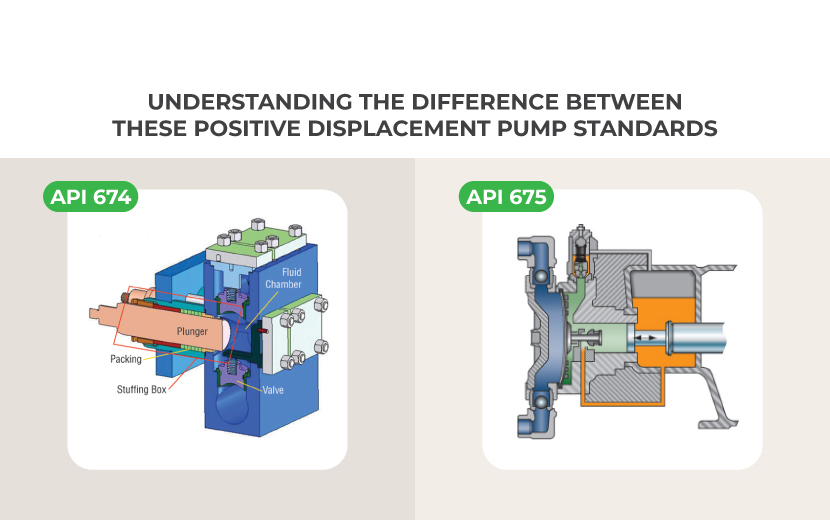

API 674 vs API 675: Understanding the Difference Between These Positive Displacement Pump Standards

When it comes to industrial pumping systems, API standards play a crucial role in ensuring safety, performance, and reliability. Two commonly referenced standards for positive displacement pumps are API 674 and API 675. While both originate from the American Petroleum Institute (API), they apply to different types of pumps and serve very different applications.

In this article, we break down the key differences between API 674 and API 675, helping you understand when and where each standard is applicable.

What is API 674?

API 674 is the standard that covers reciprocating positive displacement pumps. These pumps use a plunger or piston to displace a set volume of fluid with each stroke, making them ideal for high-pressure, low-flow applications.

Key Characteristics:

-

Covers reciprocating (piston or plunger) pumps

-

Designed for continuous, heavy-duty industrial use

-

Commonly used in oil & gas, chemical, petrochemical, and power generation industries

-

Operates at medium to high pressures

-

Suitable for slurries, hydrocarbons, water, and other process fluids

API 674-compliant pumps are valued for their durability, reliability, and ability to handle harsh operating conditions.

What is API 675?

API 675 applies to controlled-volume metering pumps, also known as dosing pumps. These pumps are designed to deliver precise amounts of fluid and are often used where accuracy and repeatability are critical.

Key Characteristics:

-

Covers diaphragm and plunger-type metering pumps

-

Designed for low-pressure, high-accuracy dosing

-

Ideal for chemical injection, water treatment, pharmaceutical, and food processing

-

Offers accurate and adjustable flow rates

-

Operates at low to medium pressures

API 675-compliant pumps are known for precision dosing, leak-free design, and compatibility with corrosive or hazardous chemicals.

Key Differences briefly

|

Feature |

API 674 |

API 675 |

|

Pump Type |

Reciprocating Pump |

Metering (Controlled-Volume) Pump |

|

Flow Type |

High-pressure transfer |

Precise, controlled dosing |

|

Pressure Range |

Medium to High |

Low to Medium |

|

Flow Accuracy |

Standard |

High (±1% or better) |

|

Applications |

Oil & Gas, Refineries, Power |

Water Treatment, Pharma, Chemical Dosing |

|

Sealing |

Mechanical seal or packing |

Mostly diaphragm-based for leak-proof performance |

Choosing the Right API Standard

The selection between API 674 and API 675 depends entirely on your process requirements:

-

If you need robust pumps for moving fluids under high pressure, such as in pipeline injection or chemical transfer, API 674 is the appropriate standard.

-

If your application involves precise chemical dosing at lower pressures, API 675 is the better fit.

Understanding the differences ensures that you choose a pump that meets both performance and safety needs.

Goma’s API 674 Pump Solutions

At Goma, we specialize in reciprocating pumps designed as per API 674 standards. Our solutions are trusted across industries for handling high-pressure operations with efficiency and reliability. Each pump is engineered to meet rigorous specifications and tested for long-lasting performance in demanding environments.

Contact us today to learn more about our API 674 compliant pumps or request a custom solution for your process.