25 October 2024

Improving Oil Recovery with Goma’s API 674 Reciprocating Pumps and The Role of Polymer Injection.

In the competitive oil industry, maximizing production efficiency is essential. Polymer injection, which enhances fluid viscosity, plays a crucial role in improving oil recovery. Goma’s advanced API 674 reciprocating pumps are specifically designed for this application, optimizing the extraction process. In this blog, we’ll explore how Goma’s Role in Polymer Injection and the advantages of reciprocating pumps.

How Does Polymer Injection Improve Oil Production?

Polymer injection is an effective enhanced oil recovery (EOR) technique. It involves introducing high-molecular-weight polymers into oil reservoirs to increase the viscosity of the displacing water. This thicker water enhances the sweep efficiency of water floods, allowing more oil to be pushed toward production wells and reducing the chances of water bypassing oil, especially in heterogeneous reservoirs.

By improving the mobility ratio between oil and water, polymer injection decreases the energy required for extraction and stabilizes the oil-water interface. This reduces interfacial tension, making it easier for oil to move. This method is widely used in the industry to maximize hydrocarbon extraction and extend the productive life of oil fields.

Goma's Role in Polymer Injection

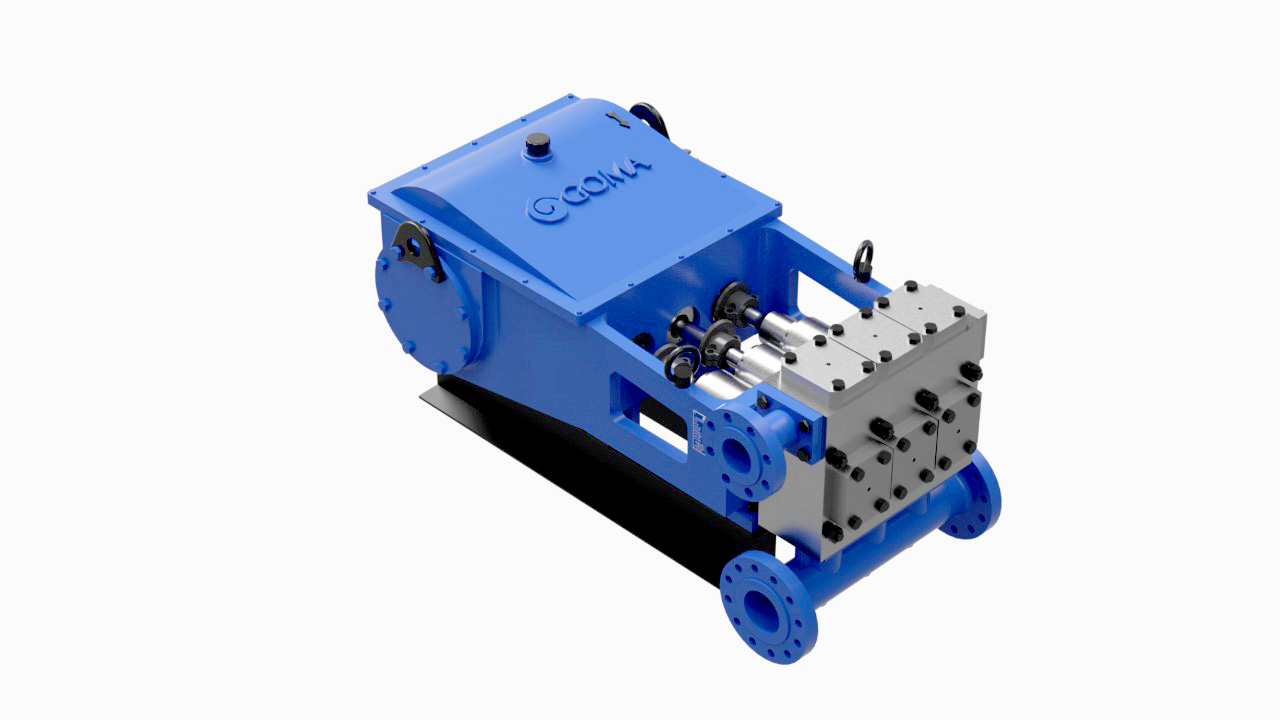

We specialize in providing high-performance Reciprocating Pump designed specifically for polymer injection applications. These pumps are engineered to deliver:

1. Precision Flow Control

Goma pumps are designed to deliver precise and controllable flow rates, ensuring a consistent polymer concentration that is essential for the injection process.

2. High-Pressure Operation

These pumps are engineered to withstand high pressures, allowing them to function efficiently in deep and intricate reservoirs.

3. Viscous Fluid Handling

Goma's pumps efficiently manage high-viscosity polymer solutions, ensuring optimal performance without risk of blockage or failure.

4. Modular Design & Flexibility

Goma's reciprocating API674 pumps have a modular design, allowing customization for specific injection rates, pressures, and viscosity requirements, enhancing operational flexibility in diverse reservoir conditions.

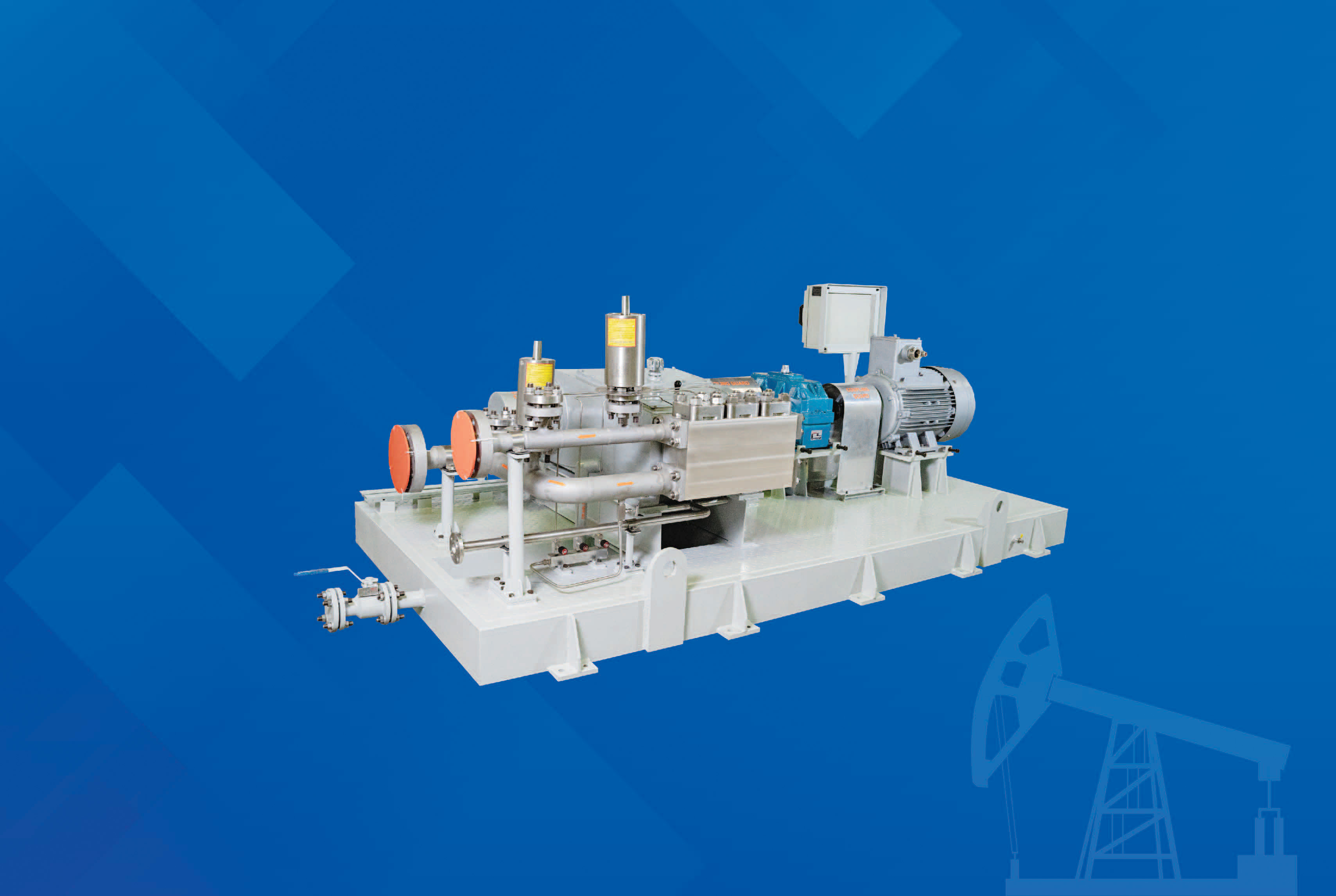

5. Versatile Packaging Capabilities

Goma provides customized packaging solutions to meet the specific needs of our customers, including:

- Power Drive: We provide electric motors with optional variable frequency drive (VFD) operation, as well as gas or diesel engine-driven packages suitable for both safe and hazardous area applications, all in compliance with project specifications.

- Auxiliaries: Our gearboxes comply with AGMA-6013 standards, and we offer optional geared motors for a more compact footprint. Our couplings also meet the standards of API-671.

- Accessories: We supply bladder accumulators and maintenance-free suction and discharge pulsation dampeners according to ASME Sec VIII Div I, with optional U-stamping. Additionally, we include gate, globe, and check valves as required.

- Safety Features: Our offerings consist of pressure safety valves that comply with API 526, as well as pressure, vibration, and temperature transmitters and switches to ensure a comprehensive safety system.

Goma's Comprehensive Pump Solutions

We offer a wide range of reciprocating pumps, ranging from 3 HP to 2700 HP, providing efficient processing capabilities tailored to various oil recovery needs. Our commitment to innovation and quality ensures that operators can rely on Goma for effective polymer injection solutions.

Polymer injection is a powerful technique for improving oil recovery, and Goma’s high-performance reciprocating pumps are essential for implementing this method effectively. With their precision, reliability, and versatility, Goma pumps play a crucial role in helping the oil industry maximize production efficiency. Partner with Goma to elevate your oil recovery processes and achieve greater success in your operations.