High-Pressure Guns are handheld devices that control water flow from the pump to the nozzle, designed to withstand high pressures and provide ergonomic comfort and control for the operator.

Dump Guns: These are specific types of high-pressure guns used to release or “dump” high-pressure fluids rapidly. They are often used in applications where quick and controlled release of fluid is necessary.

Shut-Off Guns: These guns feature a shutoff mechanism that allows operators to stop the flow of fluid quickly and efficiently. This is particularly useful in situations where precise control over fluid flow is critical, such as during shutdowns or maintenance.

Valves operated by foot to control water flow hands-free, ideal for surface and tube cleaning tasks.

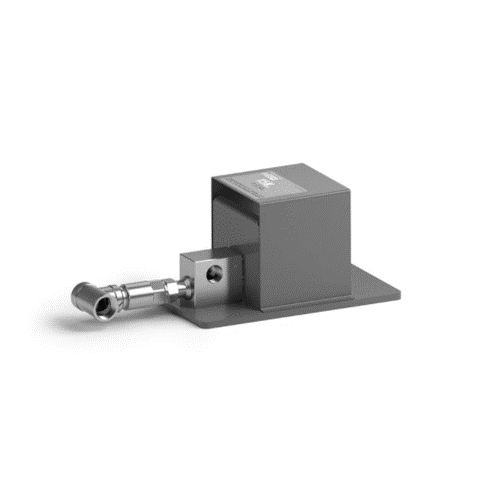

Valves that maintain constant pressure in the water jetting system, ensuring consistent performance, and preventing damage from excessive pressure.

Rupture Discs are pressure-sensitive safety devices that prevent overpressure situations by rupturing at a predetermined pressure, releasing excess pressure to protect the system.

Safety Valves automatically open when pressure exceeds a safe limit, providing additional protection against overpressure and ensuring operator and equipment safety.

Essential components connecting the water jetting pump to the nozzle, designed to withstand high pressures, provide flexibility for manoeuvrability, and ensure efficient water flow and durability in industrial environments.

Fan Jets: Nozzles that produce a wide spray pattern, ideal for covering large surface areas efficiently during tasks such as cleaning walls, floors, or vehicles.

Straight Jets: Nozzles that produce a powerful, concentrated stream of water, effective for removing stubborn deposits or coatings from surfaces and providing precise cleaning or cutting capabilities.

Forward/Backward Jets: Nozzles allowing directional control of the water jet, used for applications requiring manoeuvrability and precise targeting of the water stream, such as pipe cleaning or sewer jetting.

Rotating Nozzles: Rotating nozzles, also known as turbo nozzles or rotary nozzles, produce a rotating spray pattern that enhances cleaning efficiency. They are effective for removing tough dirt, grime, and paint from surfaces by combining the impact of a solid stream with the coverage of a fan jet

Goma, an authorized dealer of Stoneage Water Blasting Tools, also provides specialized nozzles for specific applications:

Banshee™ Nozzle: Specifically designed for tube cleaning, effectively removes deposits and fouling from heat exchangers, boilers, or condensers.

Barracuda™ Nozzle: Used for surface preparation, delivers a powerful stream to remove coatings, rust, and contaminants from various surfaces.

Torus™ Nozzle: Designed for reactor cleaning, efficiently cleans internal surfaces of reactors and vessels, ensuring optimal performance and safety in chemical processing or manufacturing industries.

Flexible lances are versatile tools designed to deliver high-pressure fluids or gases to hard-to-reach areas. Their flexibility allows them to maneuver around obstacles and navigate complex environments, making them ideal for various industrial applications.

Pressure Gauges and Pressure Sensors are used to monitor and maintain the operating pressure of the water jetting system. They provide real-time feedback to operators, ensuring consistent performance and safe operation during cleaning or cutting tasks.

Safety gear and PPE are essential accessories to protect operators from potential hazards associated with high-pressure water jetting. They include gloves, safety glasses or face shields, protective clothing, and hearing protection to ensure operator safety during operation.

In-line filters and strainers are installed in the water jetting system to trap debris, particles, and contaminants from the water supply. They prevent damage of pump components and clogging of the nozzles and ensure uninterrupted operation and consistent performance of the equipment.