11 April 2022

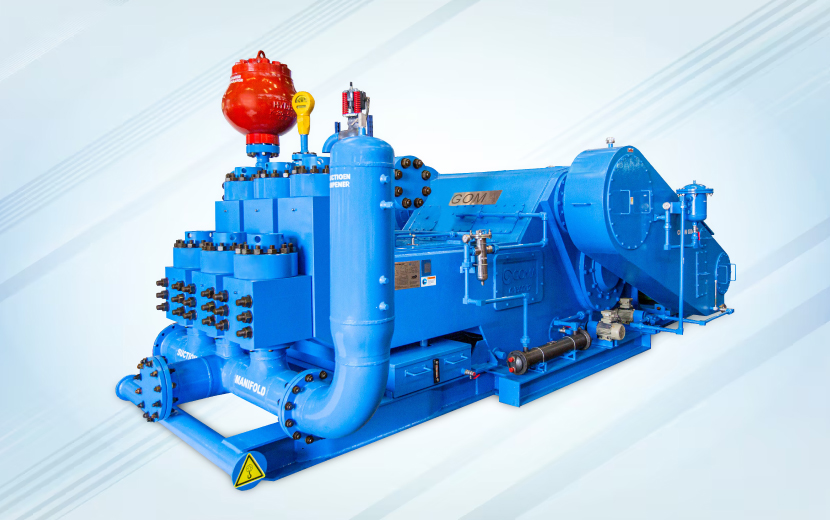

How does High Pressure Pump is Beneficial for Your Industry?

High pressure pumps work on a simple principle. They boost the pressure of water. Water with high velocity and high pressure is targeted towards the blocked and chocked surfaces to be cleaned and it removes the scaling & dirt to have the desired cleaning effects while also it acts as a pressure maintenance device for mainly process application, hydr0testing of the pipeline, valves, and vessels is a classic example of the same. Now let us dive into the details of these pumps.

Introduction to High Pressure Pumps

Triplex pumps are essentially plunger pumps with 3 cylinders and 3 heads. They are essentially used for pumping high quantity / low quantity fluid at high pressures. The flow of liquid will be continuous due to the operation of 3 plungers in a cyclical manner. The dry sections are made with specifically chosen material and manufactured to give the best performance for a long period of time. Similarly, the fluid end operations are chosen as per the customer’s requirements or demand for the fluid in the process. Our high pressure pumps at GOMA are most resourceful & highly efficient for various applications like testing, spraying, cutting, cleaning, descaling, transferring of fluids, pressure injection, etc.

What are the features of High Pressure Pumps?

Cost-effective pumps with high service life.

Rugged design for continuous duty application.

Top open power frame for easy maintenance.

Speed reduction External/Internal gearbox.

Fluid end designed for in-place replacement rings.

Gearbox or pulley-driven systems.

Application of high pressure pumps in various processes.

Furnace fuel oil injection.

Water / effluent injection.

Hydraulic testing.

Crude oil dispatch Oil/chemical handling.

Technical Specifications.

Pump Type; Horizontal, Triplex Reciprocating Plunger Pumps.

Maximum Working Pressure – up to 1500 Kg/Cm2.

Max Discharge – up to 2500 LPM.

Highest Power; 1600 HP.

Stroke Length – up 250 mm.

Power Drive ; Electric Motor / Diesel Engine/ Gas Engine.

Mounting .; Base Plate / Skid / Trolley.

Power End Connection .; Pulley Driven / Gear Box Reduction.

Characteristics

A variety of sizes in Triplex formats.

Designed in accordance with API 674, HI Standard, and IS11745.

Easily accessible service points reduce maintenance time.

Robust design for low noise and vibration characteristics.

High duty efficiency.

Extensive range capability.

Special Design Features

Excellent noise and vibration characteristics.

95% volumetric and 90% mechanical efficiency.

Spring-loaded, auto adjustment braided compression and chevron packing.

Minimizes leakage.

Valves in cartridge, easy removal and replacement.

Configurable for drives, lubrication, and skids.

What is the material used to manufacture High Pressure Pumps?

Crankcase in cast iron with customer-specific paint finish. Wetted parts can be made from a wide range of alloys including NACE compliance. High quality materials provided and NDT can be tailored to meet the project’s requirements GOMA Expertise in the field. GOMA Engineering Pvt. Ltd. is fully equipped to build and test standard centrifugal, reciprocating pump equipment and highly engineered pump systems. Additionally, it also enables GOMA to maintain a reliable supply of spare parts and efficient support for our customers from the Middle East, Indian and Asian markets.