15 September 2022

How Superfood needs super technology – Greek Yogurt & Modern Milk Processing Unit

Awareness of food products has increased in India with their globally developed palette. Greek yoghurt is one of those food products that have made its way to the regular grocery list of urban Indians. It has also evolved in the culinary scene; restaurants offering world cuisine use Greek yoghurt in ample quantity.

About Greek Yogurt

Greek Yoghurt is obtained by straining the liquid whey content from the regular yoghurt. This offers it a thicker consistency compared to regular yoghurt and has a luscious texture. It is delicious and healthy and thus, a favorite amongst healthy eaters. It has increased the content of calcium, phosphorus, and potassium. The probiotics present in Greek yoghurt are great for the digestive and immune systems. It is popular amongst Yoga and gym lovers as a workout recovery food.

Greek yoghurt has roughly double protein content, three times the saturated fat (unless you’re opting for a fat-free version), and half the carbohydrates of regular yoghurt. However, adding sweeteners to either of those increases the level.

Many Indian Dairy manufacturers have come up with their own Yogurt brands e.g. Amul, Govardhan, Nature’s Basket, Danone, etc. along with International brands such as Nestle & Britannia. It is speculated that in the coming years, Greek Yogurt will take over the regular Indian Dahi in urban India.

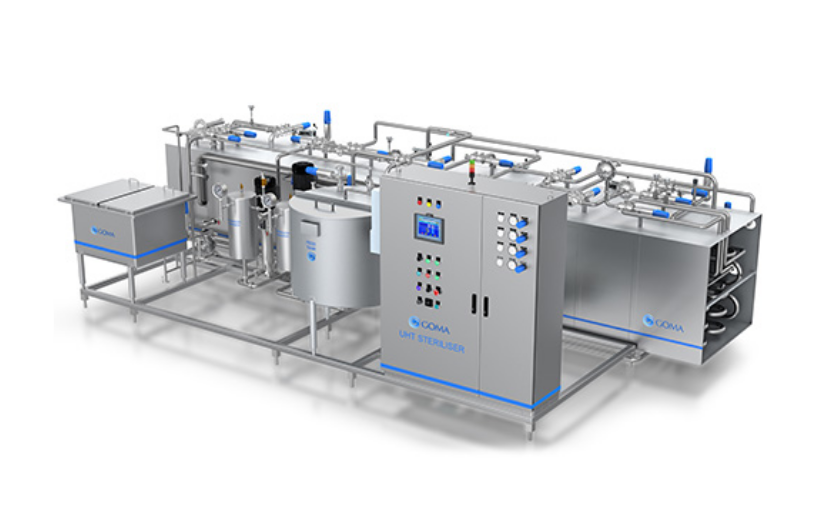

For the production of Greek Yogurt, skimmed milk is used. Our milk processing plant offers advanced techniques for the same. After acidification yoghurt is passed through a quark separator (a type of centrifugal separator) to separate water. It helps the yoghurt to achieve the desired level of concentration. Later, it is blent with the cream.

The liquid resulting from straining yoghurt is called acid whey. It is composed of water, yoghurt culture, lactose & a little amount of protein & lactic acid. Another system used in the mini dairy plants for the production of strained yoghurt is called the Ultrafiltration system.

The quality of strained yoghurt made by ultrafiltration of warm yoghurt is very similar to the traditional Indian dahi in terms of elasticity, firmness, and structure. For commercial manufacturing, Greek yoghurt can be achieved through centrifugation and ultrafiltration of regular yoghurt or dahi.

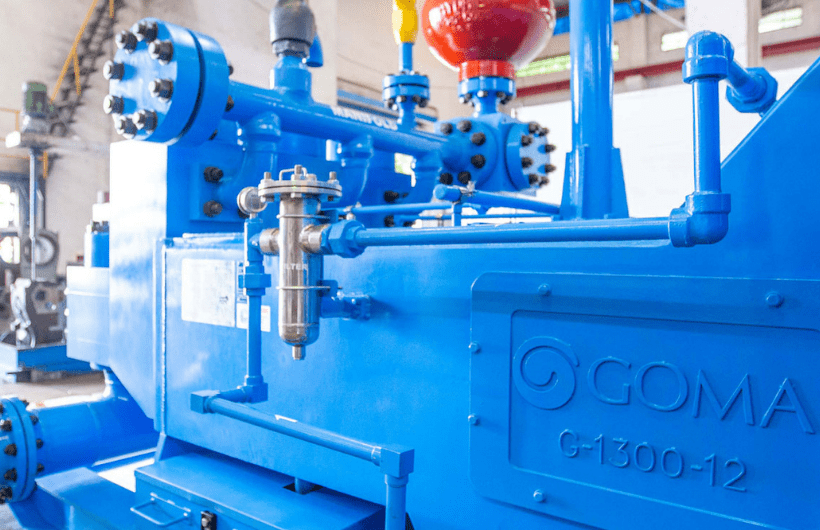

As one of the leading national & international producers of Dairy machinery and milk processing plants, GOMA ensures that the technology keeps upgrading for better quality products.

Being active in the dairy industry for the last 40 years, we constantly keep our R&D on our toes. It helps us to keep up with the changing market scenarios. As the trends keep changing, we modify our techniques and processes so that we can offer our best product range to our customers and partner with them so that they can achieve their dreams and goals.